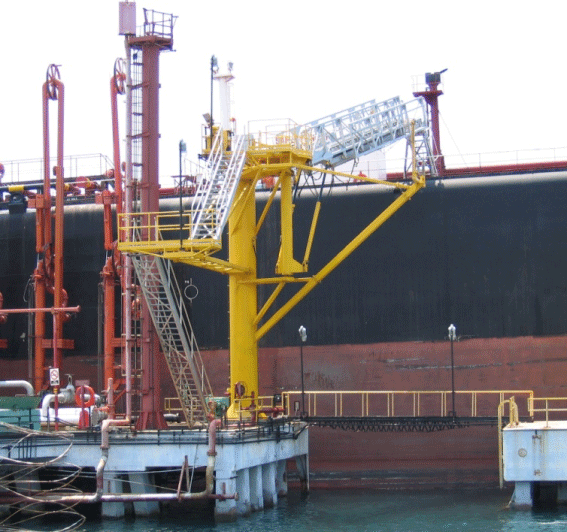

Gangway is a device for the crew of modern large oil terminal oil tankers to safely and smoothly board and disembark the ship during docking operations. Conventional boarding is done by carrying the gangway. In the development process of oil tanker terminals, modern large oil tanker terminals, especially in uncovered pier piers, the dock surface is not completely continuous, and the elevation is high, and the ship has frequent bumps and swimming during operation, and the amplitude is relatively large. Due to the large fenders of the pier, the distance from the side of the ship docked on the pier to the quay shoreline is large. The ship-to-shore connection of such conditions is difficult to solve with the gangway carried by oil tankers. Therefore, in order to speed up ship loading and unloading operations and ensure the safety of personnel getting on and off ships, it is an inevitable choice to replace ship ramps with gangways. Gangway has almost become an indispensable large-scale operating device for oil tanker terminals along with the oil transmission arm.

Although the function of Gangway is simple, but due to its environment, Gangway must have good technical performance, in order to adapt to the always turbulent conditions between ships and shores, as well as possible contingencies, the design should be on the local hydrological, meteorological data and possible arrival ships and other relevant information to make a detailed analysis, determine its adapted operating conditions, choose the correct structural scheme and reliable safety protection measures, in order to achieve the expected purpose.

The gangway designed and manufactured by Junhetongda Company has a variety of types for selection. The drive mechanism of Gangway generally adopts mechanical and hydraulic drive system, in order to ensure the safety of each transmission mechanism, various safety protection devices are set up according to the needs of the design, and all electrical devices of Gangway are selected according to the characteristics of oil products in the terminal operation.

Main technical features:

l The gangway designed and produced by our company integrates the characteristics of each gangway, overcomes the shortcomings, makes it convenient to operate, flexible, stable, safe and reliable, and convenient to maintain. l

l The main ladder can be designed as fixed-length type and telescopic type according to the requirements of the applicable ship type, to meet the deck lapping needs of the small boat type

l The step adopts a four-link mechanism, the ladder changes in the range of -45 ° ~ 85 °, and the step is always kept in a horizontal state. l

l The triangular ladder adopts a single-point connection with the front ladder, which can make the caster with spring cushioning mechanism at the bottom of the triangular ladder always have smooth contact with the ship deck, without being affected by the ship's bumps and unevenness of the deck, and at the same time use rubber or nylon casters to isolate the stray current of the gangway and the tanker. l

l The hydraulic system has reasonable layout, good sealing performance, and easy maintenance.

l The lifting mechanism has good locking performance and has an interlock function. l

l The electronic control system is independently developed and designed by the company, and the main components are selected from famous professional manufacturers at home and abroad, with reliable quality and good performance. l

l Wireless remote control makes operation more convenient. l

l The company's design and production of gangway fully complies with the following national norms and national and ministerial standards:

《Crane design specifications》

《Steel structure design code》

《Petrochemical enterprise design specification fireproof electrical appliances》

《Code for fire protection design of loading and unloading oil terminals》

《Determination of paint film thickness》

《Steel surface rust grade and rust removal grade before coating》

《Port equipment installation engineering quality inspection and evaluation standards》

《General technical conditions for hydraulic systems》

《Chemical analysis methods for steel and alloys》

《High quality wire rope》

and other latest standard versions.

Main technical parameters

Equipment gross power | 5.5~16.5kw |

Equipment weight | About 8~35T |

Working height range | 25 meters above the pier and 10 meters below the pier surface Above 25m, below 7m |

Swing angle of platform | ±90°;360° |

Working grade | M4 |

Pitching angle of main ladder | -50~+85° |

Pitch angle of front ladder | 0~60° |

Design pressure of hydraulic cylinder | 10~16MPa |

Explosion proof grade | dIIBT4 |

Protection grade | IP55 |

Type | GW × |

The variety and scope of application of our company's gangway

(一)GW1gangway

GW1 is composed of main ladder, front ladder, triangular ladder, rotating platform, traction mechanism and column. The gangway is driven by a hydraulic cylinder to achieve luffing change in the front ladder, the main ladder is pulled by a wire rope to change the luffing, and the rotary cylinder drives the rotation of the whole ladder in the horizontal plane. The lap rotary cylinder has a floating function and no counterweight. Suitable for use in terminals below 80,000 tons.

(2)GW2gangway

GW2gangway consists of main ladder, front ladder, rotating platform, lifting mechanism and tower. The gangway is equipped with multiple platforms, the triangular ladder, the front ladder, and the main ladder constitute the arm state distribution, which has a larger adaptation range, and the ladder is pushed by the cylinder to achieve pitching and telescopic. The swing cylinder telescopic drives the platform to rotate ± 90° in the horizontal plane. The slewing platform is lifted by the reducer by pulling the platform and the whole ladder through the pulley set. After lapping, the slewing mechanism and the main ladder have floating functions. This model is suitable for terminals with more than 50,000 tons.

Gangway Selection Guide The selection of Gangway mainly selects the appropriate model according to the tonnage level of the terminal, tidal changes, the status of the terminal plane, the price-performance ratio and other conditions. The user must complete the following parameter sheet and submit it to the manufacturer to determine the envelope range, base size and load data of the gangway.

Dock parameters

NO. | Description | Data |

1 | Pier front sideline to gangway centrline of gangway to edge of dock | m |

2 | Dock level | m |

3 | Design the highest water level | m |

4 | Design the lowest water level | m |

5 | Thickness of fender relaxed | m |

Thickness of fender compressed | m | |

6 | Voltage of power supply | V |

7 | Frequency of power supply | HZ |

Vessel data ( ten thousand ton~ ten thousand ton)

NO. | Description of data | Data |

1 | minimum distance of vessel flange axis to deck | m |

2 | maximum distance od vessel flange axis to deck | m |

3 | The thickness of protecting shipboard | m |

4 | Transverse drift(perpendicular to deck) | m |

5 | Total fore and aft drift(parrel to the deck) | m |

6 | Sinkage value of vessel | m |

Environment data

Description of data | Item | Data |

Maximum design wind velocity(10 meter upon the lowest water level, 3 seconds gust) | Reset state | m/s |

Movement/connect state | m/s | |

Restoration state movement.connection state earthquake factor in testoration state | Probability coefficient og earthquake Z | G |

Acceleration of earthquake force | degree | |

Environment temperature | Highest | ℃ |

Lowest | ℃ |

Copyright © 2022-2023 Junhetongda Petrochemical Equipment (Lianyungang) Co., Ltd. All Rights Reserved.

WeChat

WeChat