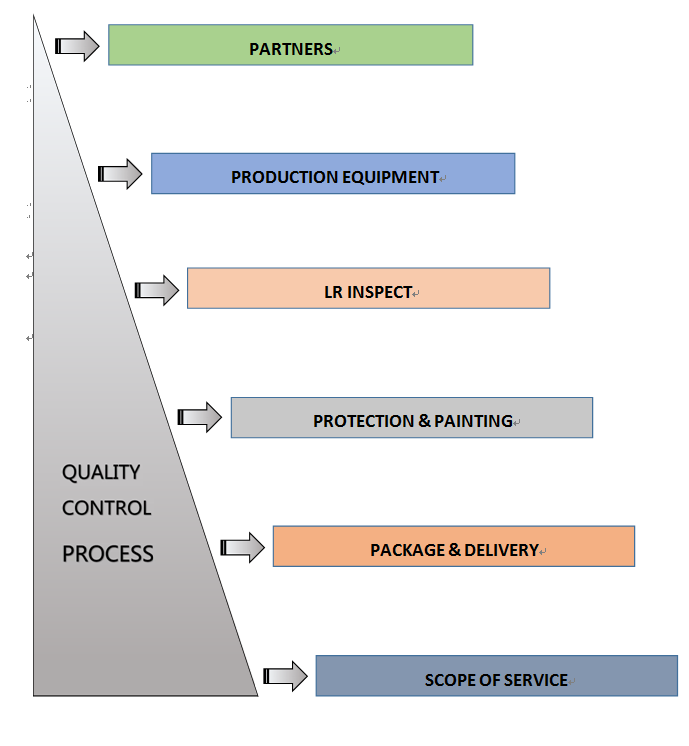

. 1、Quality Control System

quality control system from below process

Certificate

ATEX

Quick release hook require application in hazardous areas,Junhetongda Marine’s engineering is based upon possible usage in EX zone 1.When applicable we supply the appropriate ATEX certification

for our products.

Classification society inspection certificate(LR, DNVGL,ABS,BV,RINA,KR,NK,CCS)

All our quick release mooring hooks have successfully been certified by almost all applicable international certifying bodies.

Inspection and testing certificate

Junhetongda marine supply inspection and test reports as following which ensure high quality and serviceability. All testing report would be submitted to owner for approval.

Factory Acceptance Test (FAT),Site Acceptance Test (SAT),Load test report Certificate of raw material,Inspection report of repaired welding line

Inspection of electric parts,Record of blasting inspection,Assemble record of mainframe Mainframe debugging record,Coating thickness inspection,Packing inspection record Shipping inspection record

PRODUCTION EQUIPMENT

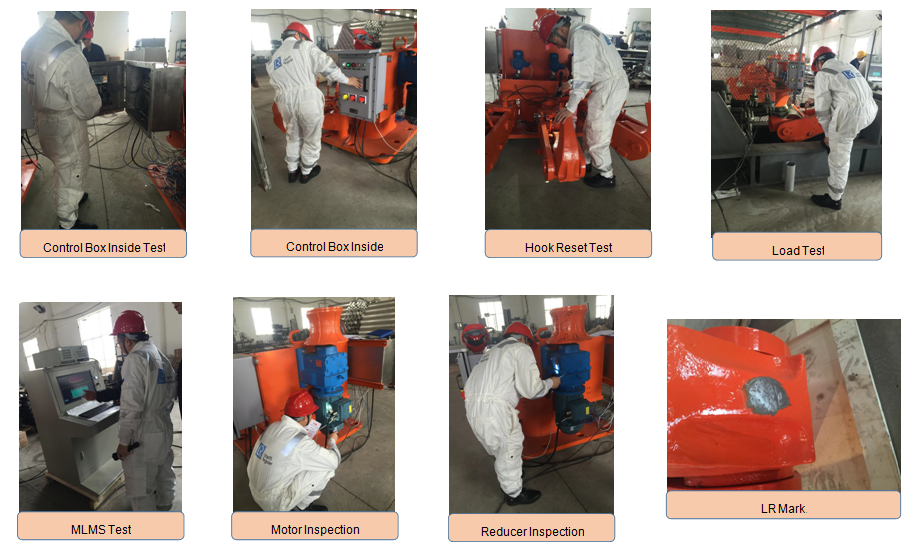

LR INSPECTION

To meet the high duty cycles and severe offshore and environmental conditions,JUNHETONGDA MARINE manufactures all equipment within her product line out certified high grade steel plates and electrical equipment. All load bearing parts are supported with necessary material certificates.

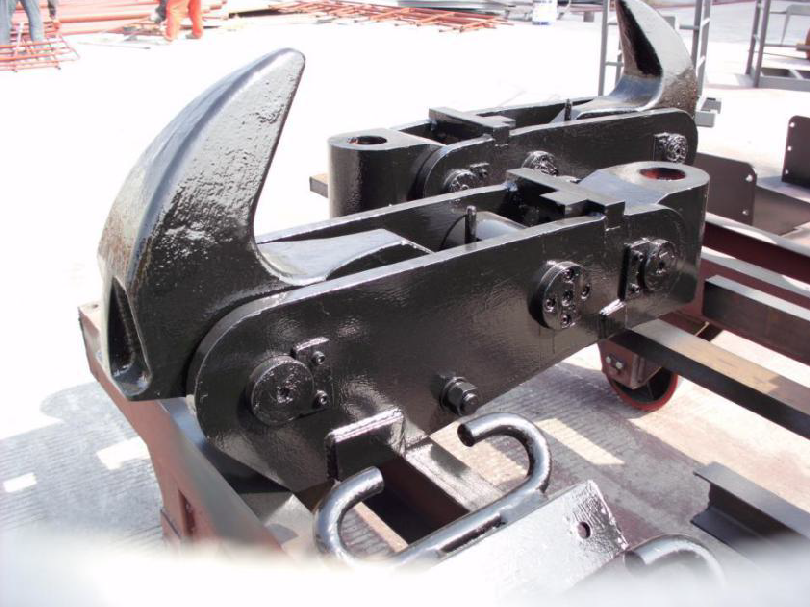

PROTECTION & PAINTING

Considering humidity and corruption of the environment, surface preparation and painting will be performed in accordance with painting specification. We will submit to the purchaser our painting procedure based on painting specification.

SURFACE PREPARATION

Oil, grease, wax, dirt and others will be removed by cleaning and degreasing from metal surfaces in accordance with SSPC SP1. Before and after blasting, all welding seams shall be closely inspected for the presence of welding flux and spatters, slivers, inclusion, burns, sharp edges and underlying mill scales. Imperfections shall be mechanically removed, welding porosity’s and welding pinholes will be eliminated and the involved area will be reblasted to standard. Sharp edges shall be rounded (R>2mm at minimum).

The quality of all prepared surfaces will be examined in accordance with Painting Specification to confirm that their requirements have been met in full prior to the application of any paint.

PAINTING INSPECTION

All result of tests listed in painting specification will be recorded in paint daily report. Coating inspectors appointed by the purchaser are welcome to check paint work during or at the end of work. We will prepare a paint work planning and advice the purchaser before the date of blasting operation.

PAINT APPLICATION

The time elapsed between surface preparation and primer coat application shall not exceed 4 hours. In any case, just prior to coat, the surface cleanliness shall be checked as specified in painting specification. Blast cleaned surfaces shall not be left unpainted during night. Prior to apply the following coat, previous coat shall be rendered free of dust, grease and other foreign matters. The quality of coating application shall be inspected in accordance with painting specification to confirm that the purchaser’s requirements have been met in full.

lSurface preparation: Shot blasting SA 2½ and hand cleaned.

lPrimer: One coat of Zinc silicate, 100 microns DFT

lIntermediate coat: one coat micocius iron oxide paint, 100 microns DFT, one coat high built high solids epoxy, 125 microns DFT

lTop coat: two coats acrylic polyurethane, 50 microns DFT/coat

|  |  |

PACKAGE & DELIVERY

JUNHETONGDA MARINE have much experienced in the efficiently deliver the goods on the customer’s site. We work closely with knowledgeable worldwide transporters. All goods are professionally packaged according to ISPM-15.

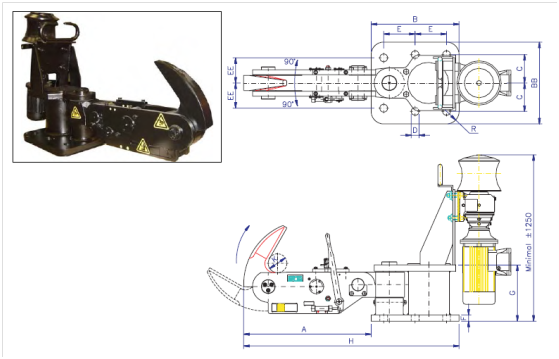

2、Type of quick release hook

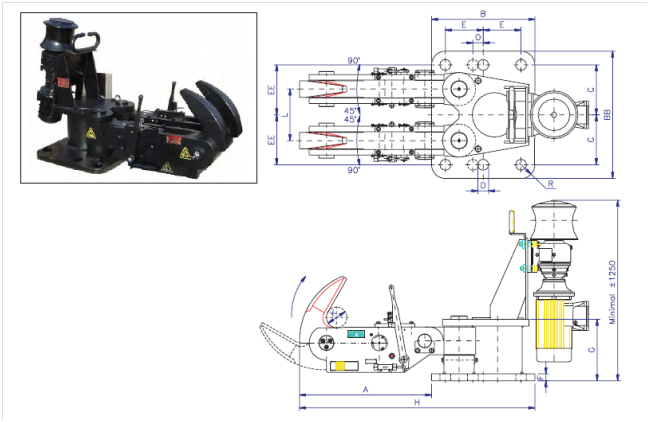

TYPE | S.W.L(KN) | RUNNING PULL(KN) | WEIGHT(kg) | A | B | BB | C | D | E | EE | F | G | H | K | R | X |

QRH-1-40 | 400 | 10 | 304 | 668 | 600 | 600 | 225 | 54 | 225 | 225 | 35 | 370 | 1268 | 96 | 75 | 4×M48 |

QRH-1-60 | 600 | 10 | 512 | 873 | 650 | 650 | 225 | 54 | 235 | 200 | 45 | 407 | 1523 | 130 | 90 | 6×M48 |

QRH-1-75 | 750 | 10 | 587 | 923 | 650 | 650 | 225 | 62 | 225 | 200 | 45 | 417 | 1573 | 130 | 100 | 6×M56 |

QRH-1-100 | 1000 | 20 | 792 | 1014 | 700 | 650 | 225 | 62 | 250 | 200 | 50 | 447 | 1714 | 150 | 100 | 6×M56 |

QRH-1-125 | 1250 | 20 | 887 | 1085 | 700 | 650 | 225 | 70 | 250 | 200 | 55 | 479 | 1785 | 150 | 100 | 6×M64 |

QRH-1-150 | 1500 | 20 | 1210 | 1255 | 700 | 650 | 225 | 78 | 250 | 195 | 55 | 499 | 1955 | 150 | 100 | 6×M72 |

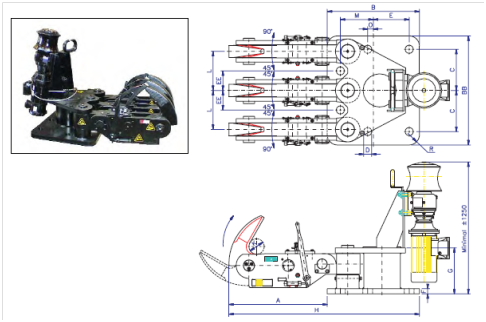

TYPE | S.W.L(KN) | RUNNING PULL(KN) | WEIGHT(kg) | A | B | BB | C | D | E | EE | F | G | H | K | R | X |

QRH-2-40 | 400 | 10 | 491 | 583 | 650 | 700 | 260 | 54 | 235 | 260 | 35 | 370 | 1233 | 96 | 90 | 6×M48 |

QRH-2-60 | 600 | 10 | 878 | 788 | 750 | 780 | 290 | 62 | 275 | 290 | 45 | 407 | 1536 | 130 | 100 | 6×M56 |

QRH-2-75 | 750 | 10 | 1049 | 888 | 750 | 850 | 325 | 70 | 275 | 325 | 45 | 417 | 1638 | 130 | 100 | 6×M64 |

QRH-2-100 | 1000 | 20 | 1439 | 959 | 750 | 925 | 363 | 78 | 275 | 363 | 50 | 447 | 1709 | 150 | 100 | 6×M72 |

QRH-2-125 | 1250 | 20 | 1602 | 1030 | 750 | 925 | 363 | 86 | 275 | 363 | 55 | 479 | 1780 | 150 | 100 | 6×M80 |

QRH-2-150 | 1500 | 20 | 2332 | 1210 | 750 | 1000 | 400 | 86 | 275 | 400 | 55 | 499 | 1960 | 150 | 100 | 7×M80 |

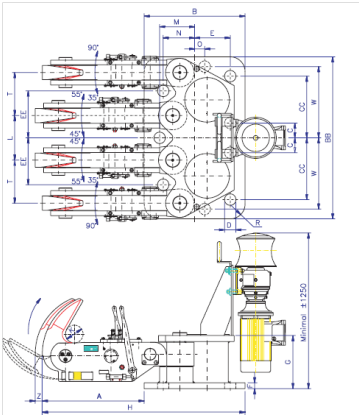

TYPE | S.W.L(KN) | RUNNING PULL(KN) | WEIGHT(kg) | A | B | BB | C | D | E | EE | F | G | H | K | R | X | TYPE | S.W.L(KN) | RUNNING PULL(KN) |

QRH-3-40 | 400 | 10 | 707 | 598 | 700 | 800 | 310 | 62 | 260 | 145 | 35 | 370 | 1296 | 96 | 290 | 275 | 90 | 6×M56 | |

QRH-3-60 | 600 | 10 | 1268 | 863 | 800 | 900 | 335 | 70 | 310 | 162 | 45 | 407 | 1663 | 130 | 325 | 310 | 65 | 100 | 6×M64 |

QRH-3-75 | 750 | 10 | 1540 | 893 | 850 | 1000 | 375 | 78 | 325 | 175 | 45 | 417 | 1743 | 130 | 350 | 325 | 60 | 100 | 6×M72 |

QRH-3-100 | 1000 | 20 | 2144 | 959 | 900 | 1060 | 400 | 78 | 350 | 190 | 50 | 447 | 1859 | 150 | 380 | 322 | 55 | 100 | 7×M72 |

QRH-3-125 | 1250 | 20 | 2450 | 1030 | 900 | 1060 | 400 | 86 | 350 | 190 | 55 | 479 | 1930 | 150 | 380 | 322 | 55 | 100 | 7×M80 |

QRH-3-150 | 1500 | 20 | 3586 | 1235 | 1020 | 1200 | 475 | 96 | 385 | 212 | 55 | 499 | 2255 | 150 | 425 | 385 | 115 | 125 | 7×M90 |

|  |

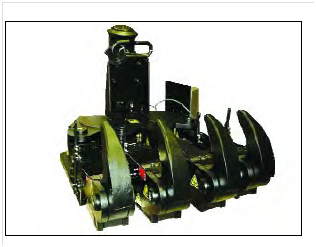

TYPE | S.W.L(KN) | RUNNING PULL(KN) | WEIGHT(kg) | A | B | BB | C | D | E | EE | F | G | H | K | R | X | TYPE | S.W.L(KN) | RUNNING PULL(KN) | WEIGHT(kg) | A | B |

QRH-4-40 | 400 | 10 | 938 | 578 | 650 | 1120 | 100 | 470 | 70 | 235 | 300 | 35 | 370 | 1228 | 96 | 300 | 235 | 235 | 90 | 300 | 40 | 7×M64 |

QRH-4-60 | 600 | 10 | 1670 | 778 | 750 | 1185 | 115 | 445 | 78 | 275 | 330 | 45 | 407 | 1528 | 130 | 325 | 255 | 230 | 100 | 320 | 56 | 7×M72 |

QRH-4-75 | 750 | 10 | 2032 | 823 | 800 | 1300 | 150 | 505 | 86 | 290 | 355 | 45 | 417 | 1623 | 130 | 350 | 280 | 265 | 100 | 340 | 50 | 7×M80 |

QRH-4-100 | 1000 | 20 | 2807 | 859 | 850 | 1365 | 125 | 520 | 96 | 300 | 395 | 50 | 447 | 1709 | 150 | 376 | 295 | 265 | 125 | 362 | 60 | 7×M90 |

QRH-4-125 | 1250 | 20 | 3199 | 930 | 850 | 1365 | 125 | 520 | 96 | 300 | 395 | 55 | 479 | 1780 | 150 | 376 | 295 | 265 | 125 | 362 | 60 | 7×M90 |

QRH-4-150 | 1500 | 20 | 4698 | 1118 | 925 | 1570 | 170 | 605 | 86 | 325 | 435 | 55 | 499 | 2043 | 150 | 426 | 325 | 280 | 135 | 415 | 60 | 9×M80 |

Copyright © 2022-2023 Junhetongda Petrochemical Equipment (Lianyungang) Co., Ltd. All Rights Reserved.

WeChat

WeChat